The biomass boilers work the same as any other boiler: they burn the biofuel generating a flame that enters the boiler. The heat generated during this combustion is transmitted to the water circuit in the exchanger incorporated in the boiler, with which hot water is obtained for the heating system or DHW (domestic hot water). In most cases an accumulator can be installed, which will store the heat to supply it instantaneously.

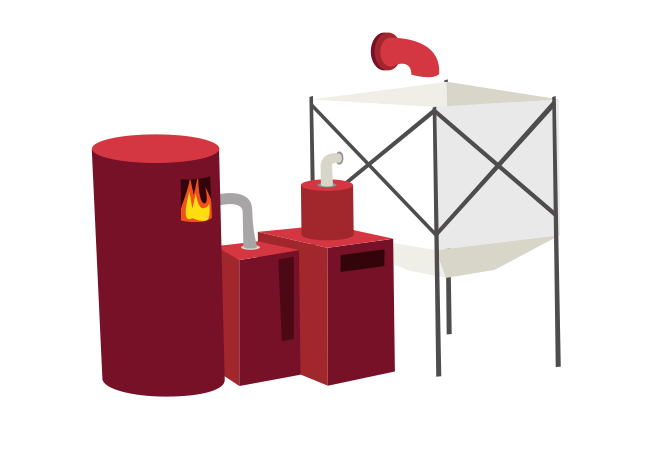

Biomass boilers need a container or silo for storing the biofuel located near the boiler. From this silo, an auger or suction feeder will drive the biofuel to the boiler, where combustion takes place. The combustion of biofuels produces ash, which is automatically collected in an ashtray that must be emptied several times a year.

Biomass boilers can be classified according to the type of fuel they admit and the kind of technology they use.

According to the type of fuel

• Pellet boilers.

They are usually small and highly efficient. Stresses its compactness due to the stability of the pellet, and in some cases can use other biofuels with similar characteristics provided that the manufacturer guarantees it. They are usually manufactured for medium and low power.

• Polycombustible biomass boilers.

They admit several types of fuel, even changing from one to another quickly and efficiently, such as pellets and chips. They are usually manufactured for medium or high power.

Depending on your technology:

• Conventional boilers adapted for biomass.

They are usually old coal boilers adapted to be used with biomass or diesel with a biomass burner. Although they are cheap, their efficiency is reduced, standing around the 75-85%. They are usually semi-automatic since, since they are not specifically designed for biomass, they do not have specific maintenance and cleaning systems.

• Standard biomass boilers.

Designed specifically for a specific biofuel (pellets, chips, firewood, ...), they reach yields of up to 92%. These are usually automatic boilers, since they have automatic systems for feeding the fuel, cleaning the heat exchanger and extracting the ashes.

• Mixed boilers.

Mixed boilers allow the alternative use of two fuels, making it possible to change from one to another if the economic or supply conditions of one of the fuels so advise. They need a storage and a boiler feed system for each fuel, so the investment cost is higher than for other technologies. Its performance is high, close to 92%, and are fully automatic boilers.

• Condensing pellet boilers.

Small, automatic and for exclusive use of pellets, these boilers recover the latent heat of condensation contained in the fuel by progressively lowering the temperature of the gases until the water vapor condenses in the exchanger. A performance of up to 103% is achieved.

Installations of boilers whose power is greater than 70kw must take into account the considerations for a boiler room of the RITE (Regulation of Thermal Installations in Buildings) and for installations of less than 70 kW the manufacturer's and installer's instructions must be considered. On the other hand, remember that the installation of biomass boilers of atmospheric type, that is, in which the fireplace or combustion chamber is at ambient pressure, which are the majority, is allowed based on the RITE itself and the Royal Decree 1027 / 2007.

Own elaboration. Source IDAE, AEBIOM, CALORYFRIO