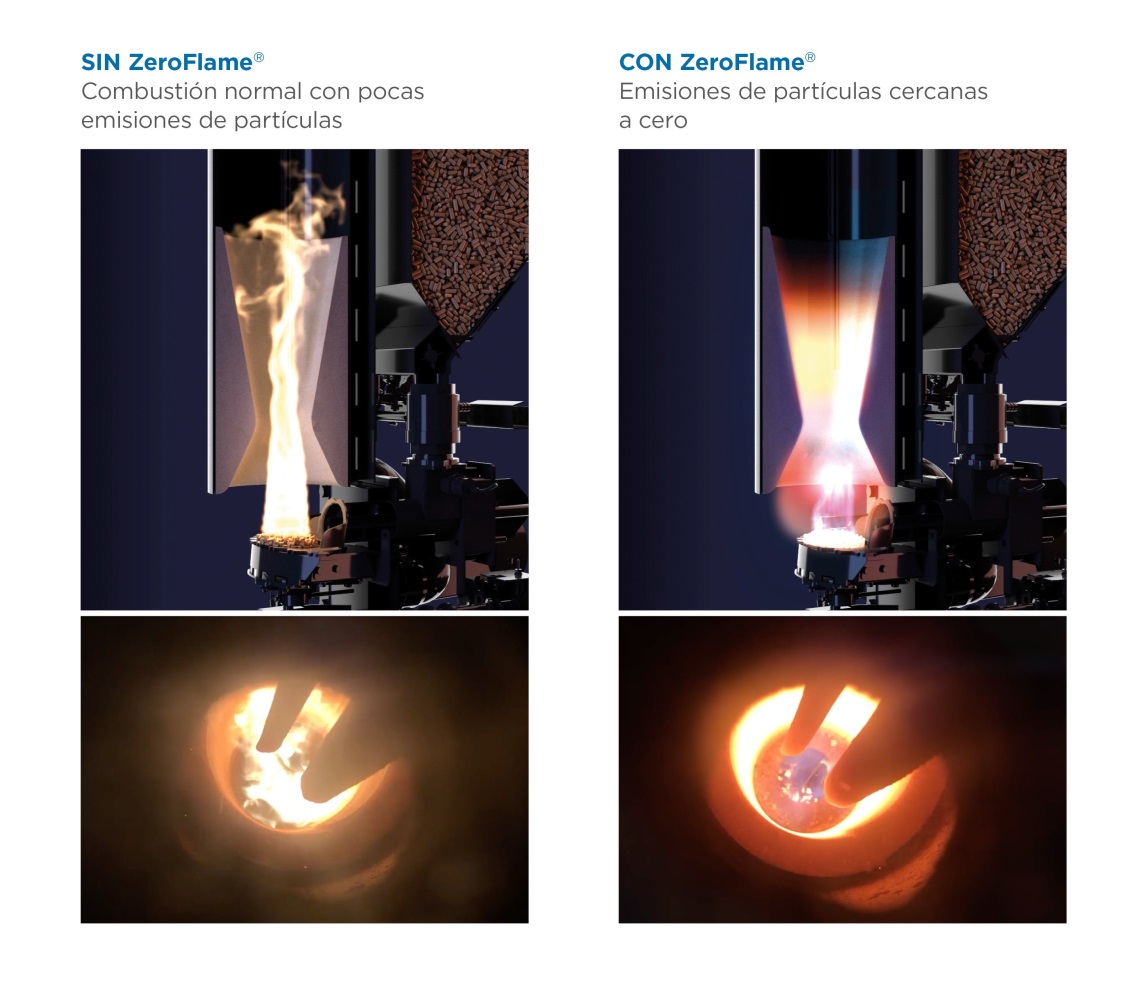

This system was tested in the TÜV laboratories. In a cyclical test simulating the various operating conditions throughout a year, an average particulate emissions of just 2 mg / m3 (13% O2) were measured. This level of practically negligible emissions is achieved with a new design of the flame tube in the combustion chamber, and a divided recirculation of the exhaust gases. These gases feed the primary air in the lower zone and are injected in the upper burning zone at high temperature. In this way we achieve a fire WITHOUT FLAME, and a minimum emission of particles.

The alternative on the market to this technology is the use of filters, so the advantages of ZeroFlame are clear: without the need for a high investment, without special maintenance, without high voltages, and it works in all phases of operation of the pellet boiler.

Today, this technology is available for the OkoFEN Pellematic Condens model, a condensing pellet boiler from 10 to 16 kW, therefore the scope of application is mainly for heating and hot water in single-family homes.

In the near future, it will be extended to the rest of the OkoFEN boiler range, up to 512 kW, so ZeroFlame will be available for heating and DHW for all types of applications: industry, hotels, farms, swimming pools, etc.

ÖkoFEN has presented this technology to the Expobiomasa 2021 Innovation Award

More info